ABSTRACT:

Metallic filament fibers and yarn have been used and known for more than 3000 years. Gold and silver have been used since ancient times as decoration in clothing and Textile. Many of these textiles can be found in museums around the world, Gold and silver were hammered into extremely thin sheets, cut into ribbons, and worked into fabrics. Examples; include magnificent Persian carpet and Indian ornamental sarees, Down through the centuries, kings and queens have worn garments that have glittered with gold and silver fibers twisted wrapped around cotton or some other thread. They have been woven on byzantine looms from 7th to 9 th centuries, and after that in Sicily, Cyprus, Lucca, and Venice. Weaving also flourished in the 12th century during the legacy of Genghis Khan. When art and Trade flourished under Mongol\rate in china and some Middle Eastern Areas. The Dobeckmun company produced the first modern metallic fiber in 1946. currently, metallic fibers are manufactured primarily in Europe and none are made in the united states. In the past aluminum has always been used as the base in a metallic fiber. more recently stainless steel has become base as well. It is more difficult to work with but provides properties to the yarn that allows it to be used in a more high-tech application. (2)

INTRODUCTION

10

year after their first industrial use, metal fiber is now widely produced and

available in different forms. and their increasing use in industrial

applications is driven by a combination of high electrical conductivity and

excellent high thermal corrosion resistance Radar Reflecting property, yet are

lightweight and flexible. The various method has been developed to coat fiber and

Textiles materials by metals.(2)

- Coating metal powder with binders.

- Sputter coating

- Electroless coating

- Vacuum deposition

So many technical applications

demand properties which can not be obtained by simply processing common textile

material into the single textile fabric. However, a combination of knitted

structure, textile, and metal yarn of wire make it possible to create innovatively

products for multipurpose technical applications. Thus knitted fabrics are

flexible and extensible and metal wire possess properties that are

advantageous in technical textile with regard to their permanent antistatic

behavior, known conductivity, shielding from electromagnetic field and Resistance

to cutting.

This

paper provides an overview of the production process involved in metal fiber

production, the various type of metal fiber products, and also their key

properties and a short summary of the main application segment. (3)

DEFINITION

A

metal fiber can be defined as a manufactured fiber composed of metal, metal

coated plastic or a plastic-coated metal or a core completely covered by

metal. (1)

MANUFACTURING

PROCESS OF METAL YARN:

There are two basic methods of manufacturing metallic fibers.

The most common method is the laminating process.

The Raw material used is a roll of aluminum

foil of 0.00045-inch thickness and 20 inches wide. On both side of the Aluminum

sheet Adhesive films (Thermoplastic) is applied and also the required coloring

matters are added: Then the Adhesive coated foil is heated to about

90-95c. After that transparent sheet

(sheet of cellulose Acetate butyrate)is laminated to each side of the Aluminium

foil. Bypassing through squeeze rollers (At a pressure of 200lb/in) The laminated

Aluminum foil is then cut Slits into the filaments form with the required length

and width. (2)

METHODS OF METAL COATING:

- Metal coating with binder

- Vacuum decomposition

- Sputter coating

- Electro less plating

Metal coating with binder:

This process is similar to conventional polymer coating.in which, high leafing aluminum um pastes (60-70%)are incorporated into a polymeric carrier. Like PVS, polyurethanes, synthetic rubbers, silicon etc, and then spread onto the surface of the fabric (coated on fabric). the coating method may be used a conventional knife and roller coating. (2)

Vacuum Decomposition:

Vacuum decomposition

is a generic term used to a deposited a layer of material onto the substrate. The

type of coating includes materials (cadmium, chromium, copper, nickel, titanium). In this process, the substrate (material)to

be coated is placed. in a chamber over a set of crucibles. A crucible containing

the metal to be coated to the substrate in the form of powder/wire. After that crucible is heated with

resistance heating to melt the metal. The temperature of the heating is adjusted

that the vapor pressure of the metal. Exceeds that of the chamber pressure, so

that. substantial evaporation of the

metal takes place. The metal is placed into the crucial and heating the metal is

continuing to convert the metal into the molten metal. Heating the crucial is

continue so that evaporation of metal takes place. Evaporated metals.is placed

is goes in the upward direction where the web is placed onto the substrate. evaporated metal is coated onto the surface of the web and

condenses in the form of a solid. metal as it passes over the crucible. The production speed is quite high, ranging

from150-500m/min. The difficulty arises in the case

of metal, which sublime rather than melt and boil. (2)

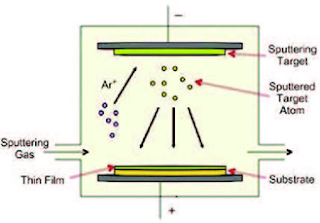

SPUTTER

COATING:

This is another method of metal coating. which consists of a vacuum chamber containing inert argon gas. usually argon at 10-3 to 10-1

tar. The chamber which is equipped with a cathode (Targeted at the anode, which is acts

as substrate) Application of an electrical potential of the order of 1000V D,

between the two electrodes, produces a glow discharge. A flow of current. occurs

due to the movement of electrons from the cathode to anode. The electrons ionize the argon gas and argon gas celebrated

towards the cathode.at very high speed(Target) considerable heat is generated

during the sputtering process and also it is necessary to cool the target. The

sputtered atoms and ions condense onto the substrate to form a thin film of

coating(2)

Electroless plating

Electroless plating is the process of depositing the metal film on a surface without the use of electrical energy. electroless plating also known as chemical plating or autocatalytic plating is a class of industrial chemical processes that creates a metal coating on various materials by autocatalytic chemical reduction of metal(5). The main advantage of electroless plating is that it creates a layer of metal on the surface more ever electroless plating can be applied to a non-conductive surface and part of the object that can not be connected to the current sources. In electroless plating, the metal deposit is formed as a result of a chemical reaction between reducing agent and metal ions present in solution if the deposited metal acts as a catalyst, autocatalysis occurs. And a smooth deposition is obtained .such as an autocatalytic process is the basis of electroless coating. (2)

PROPERTIES:-

- Metal fiber structure and products display excellent properties, such as high porosity, which benefits the function and structure of specific applications.

- Their low electrical resistance makes them suitable for any application that requires electrical conductivity.

- Excellent thermal resistance makes them withstand extreme temperatures.

- Corrosion resistance is achieved through the use of high-quality alloys.

- Other advantageous mechanical properties of metal fibers include shock resistance, fiber resistance, and sound insulation. (3)

APPLICATIONS

Esd/Emi protection

Metal fibers are used to protect a

variety of products against ESD and EMI such as big bag brushes, carpets &upholstery fabrics, plastic compounds, and personal protective clothing.

Filtration

Filtration applications range from diesel and gasoline particulate filtration, gas filtration, HEPA filtration, hydraulic fluid filter media, inkjet filtration, marine fuel & lube oil filtration media, polymer me filtration, and crankcase ventilation filter media.

Heating

Specific applications in this segment includes car seat heating, heatable clothing, and SCR heating.

Hot glass manipulation

Stainless steel textiles offer unique advantages during the production of automotive glass, automotive mirrors, ballistic glass, container/hollow glass, and solar glass

Specialties

This segment includes applications such as brake pads and clutches; composite reinforcement; cut-resistant gloves; heat pipes; regenerator materials; seals, packing & gaskets; smart textiles; sound attenuation; and cooking ware forming. (4)

FUTURE SCOPE

- Multi-Functional Textiles

- Sensing yarn, woven/knitted into garments.

- Intelligent textile applications.

- Hearable textiles as the heating element.

- Conductive seam ribbons for Cleanroom garments.

- Stimulation electrodes knitted into garments.

- Wearable /knittable lead wires.

- Hearable textiles.

- EMI Shielding wall-coverings and other textile structures. (4)

CONCLUSION:

The metallic fibers and yarns have taken the textiles to the next level in technical textiles more specifically in conductive and smart textile materials. Metal fibers and yarns have made entry into the fiber and fashion industries. Besides aesthetic effects, they also provide stability to the structure, electromagnetic shielding, and wearable textiles materials are also produced from the metallic fibers and yarns. In the future, these applications are expected to increase with the ever-increasing use of electronic goods and personal protection devices(3)

REFERENCES:

1- Federal Trade Commission Definition

2- "Metal fiber

products". Bekaert. Retrieved 2019-06-04.

3- An introduction to Metal Fiber Technology - White Paper (https://www.bekaert.com/en/product-catalog/content/Metal-fibers/replacement-of-glass-fiber-media-by-metal-fiber-media)

4- An Overview of Metal Fiber Applications" - White paper - J.De Baerdemaeker, J.Vleurinck

5- www.wikipedia.metal - fibers.com

1 Comments

Really a good article that may open the eyes of industry stalwarts to think of new vistas in technical textiles. The article has incorporated useful information on such traditional technology of manufacturing such specific items and indicates the ways how it will be useful in modern age of life.

ReplyDelete