Veermata Jijabai Technological Institute, Mumbai, India

Textile mills require huge number of raw materials for conversion of those raw material into the final product for this purpose the mills use large number of machine and processes. When the raw material is been converted into a final product the material is transferred from one department to other and different machines are also used. Each mill has a targeted production and to achieve this the mill management requires safe sufficient and economical material handling.

1. DEFINITION

OF MATERIAL HANDLING AND ITS ADVANTAGES

Material

handling can be defined as the “art and science of conveying, elevating,

positioning, transporting, packaging and storing of materials”.

- Raw materials such as fibers for spinning unit or yarns for weaving enters the mills and goes out of the mill in the form of a fully developed product, it is handled at all stages, in different machines and departments.

- Materials handling cost is roughly 10-30% of the total production depending upon the product manufactured.

- By saving on the material handling cost, the cost of production can be reduced.

- Material movement adds to the cost, material handling involves the movement of materials manually or mechanically.

ADVANTAGES

OF PROPER MATERIAL HANDLING OFFER THE FOLLOWING BENEFITS:

- Reduce manpower

- Reduce production cost

- Improve productivity

- Increase the speed of material movement

- Locate and stock material better and in less space

- Reduce material wastage

2.

FUNCTION OF MATERIAL HANDLING SECTION

- Select appropriate material handling equipment that is safe and full fill material handling equipment at low possible cost.

- Select production machines and place those machines in plant layout so as to reduce as far as possible the need for material handling.

Example: - In spinning unit chute feed cards

3.

SELECTION OF MATERIAL HANDLING EQUIPMENT

Following

are the factors affecting the selection of material handling equipment

Type/shape of the material to be transported

The

size of the material, its shape, weight, and its chances of getting damaged during

handling, etc. should be considered.

Machine

production

The different machine has different outputs per unit of time. The material handling equipment

should be able to handle the maximum output.

Type

of material flow pattern

A

horizontal flow pattern will need trucks, overheads, bridge, crane, conveyors

etc. where as a vertical flow pattern will require elevators, conveyor and

pipes.

Other

factors

Other

factors also considered during selection of material handling cost are: cost of

material handling equipment, handling cost, life by the equipment and the

amount of care and maintenance required for the equipment.

4.

MATERIAL HANDLING EQUIPMENTS

A

wide range of material handling equipment is available the market which are

suitable to the most of the industrial requirements. Material handling

equipment are classified as:

- Industrial trucks

- manual and powered. In most cases, cotton or polyester ice, raw material in the form of bales are I supplied to the mill through

- Cranes

- overhead bridge crane, jib crane, and gantry crane

- Hoists

- chain type manual, electrical and pneumatic

- Conveyors

- conveyors, roller conveyor, drag conveyor etc.

- Monorail

- Slides and chutes

- Lift

- Tractors and trailers.

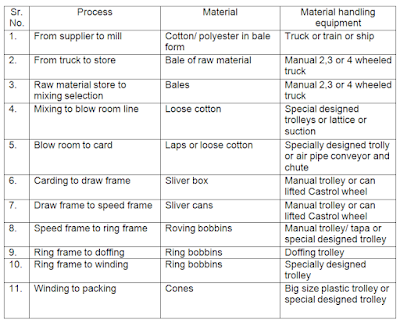

MATERIAL

HANDLING IN SPINNING UNITS

SOME

HANDLING EQUIPMENT

0 Comments