Objects of Doubling and

Twisting:

Twisting is the process of

formation of yarn where twisting of two or more yarns together to form a single

twisted yarn.

Objects of doubling and

twisting are done in order to achieve:

- More stronger yarn

- More regular yarn

- Novel and fancy effects

- Yarns for different purposes.

Doubling and twisting are two separate operations

Doubling:

- The ring-spun yarn contains various faults which are required to be removed first on the winding machine and also at winding necessary to convert small packages into larger packages.

- Bigger packages formed contain uniform yarns, basically, it means several uniform drawn yarns are combined and wound on a package uniformly.

- Doubling is an auxiliary process where double or cable yarn is prepared for processing on twisters.

- Also in the doubling process the yarn is also cleaned from lint and waste and the weak and thicker sections are removed and the yarn is cross-wound on a cylindrical bobbin in order to make further processing easier.

The operation of the following

is performed on doublers:

- The yarn is first unwound from feed packages and the number of which equals the number of yarns to be doubled and passes over a guide rod after which it drawn through a control and cleaning device which bears a tension device and two metal plates or blades that form a slit.

- The width of the slit selected depends on the average diameter of the yarn and thus thick sections of yarn do not pass through the slit and hence break the yarn.

- The tension applied causes the yarn to break at weak points and the winding speed reaches 500 to 600 m/min.

First two or more yarns are

on a doubling bobbins came together and after that the actual twisting process

followed by twisting two or more yarns together take place.

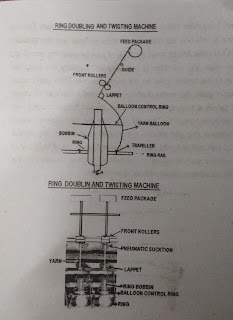

Passage of material through

Ring Doubler:

- Here no drafting system used on ring doubling machine.

- Feed packages prepared at parallel winder i.e doubling machine with two or more single yarns are placed at creel.

- Yarns are withdrawn from feed package passes over guide then through front pair of rollers both top and bottom roller are Steel rollers, top roller is plain roller whereas bottom roller is steel fluted roller.

- One spindle having one top roller and in order to have some grip between bottom and top roller and to avoid slippage of yarn between the grip of top and bottom roller the top roller is self weighted.

- Similarly flutes are provided on to the bottom roller for the same purpose.

- The yarn passes through lappet guide, the centre of which is positioned in line with the centre of spindle, then through the balloon control during which control the size of the yarn balloon.

- Then the yarn passes through the gap between ring and travelers, the traveler rotates over ring surface because of yarn pull and insert twist in the yarn coming out of front pair of rollers.

- Finally the yarn wound onto a bobbin with the help of spindle rotation.

Twist and Twist Direction

Effects:

- As per the twist directions in a single and in doubling, the yarns are known as twist on twist or weft on weft etc.

- The single yarns are usually manufactured for warp way twist i.e Z way and the general doubling yarns are weft way twisted or S way and such a double yarn us known as S on Z.

- These yarns have good luster, fullness, smoothness and are stable.

- In order to get special effects Z on Z yarns can also be produced such as voile and crepe etc, these yarns are unstable, harsh and rough.

- In doubling yarns the twist factors are generally high and they have definite relationship in comparison with their component single yarns for getting maximum effects.

For instance;

1- To get lustre ratio= Folding

Twist/ Single yarn twist=0.7

2-To get maximum strength=

Folding Twist/Single yarn twist=18 to 20

And;

3- To get maximum cohesion the

ratio is= 1.0

- When two single yarns are doubled with normal twist, the strength of the resultant double yarns is about 2.5 to 3 times the single yarn strength.

- Strongest double yarns are produced by having low singles twist and high doubling twist and when the singles twist is increased the resultant doubling yarn strength falls.

Z on Z Vs S on Z:

- In Z on Z yarns, where single yarns are low twisted, the resultant double yarn, even with low doubling twist, is fairly stronger and production of such yarns are always economical.

- Where doubling twist factors are less than 5, Z on Z yarns are always stronger.

- These yarns are more sensitive to changes of doubling twist than S on Z.

- As Z on Z yarns have more extensibility than corresponding S on Z however they have higher contraction or take up.

- It should be note that any processing, subsequent to doubling that puts high tension to the yarn, it is likely to sustain these tensions due to the strength and extension of Z on Z yarns to a greater extent than yarns of S on Z.

Properties of Double or

Folded Yarn:

- As the double yarn are voluminous (bulky), round, and fuller that means the fabric produced with this yarn will have better cover.

- It is observed that with increase in doubling twist the elongation at break of a two fold yarn get increased if singke yarn twist factor is lower than double yarn twist factor.

- Higher the doubling tension i.e speed of spindle and heavy weight traveler) produces more stronger yarn but may reduce in extensibility and with low doubling tension, produces a soft singles and folding twists are not used.

- Yarn property may affect by the tension variations such as low doubling tensions results in the higher yarn extension property whereas increase in tension leads to stronger yarn with reduced extension however snarling tendency increases with increase in yarn lustre.

- Several double yarns has tendency to untwist and snarl, to overcome this problem certain ratio of twist between single and double yarn is required to be maintained.

- The twisted yarns and fabrics which are produced from doubled yarn show more evenness.

- With the twisted double yarn a softer and pleasant fabric feel can be obtained

- Fabric prepared from twisted yarns are more durable and resistance to chaffing.

- Twisted double yarn give higher dimensional stability to the fabric.

- Special twisted yarn can produce required specific effect and character.

- The twisted yarns have better running characteristics in the subsequent process and allow a higher efficiency rate.

Application of Double Yarn:

- Doubling is a term used for folding and ply yarn also.

- The yarns may also be twisted together either in a one-stage or in several stages, either in a dry state or in a wet state.

- The yarn may also be twisted either with identical tensions or in varying degrees of tension, either twisting with similar ones or with dissimilar yarns to produce a variety of yarns such as warp, weft, sewing threads, knitting yarns, fancy yarns, lace yarns, embroidery yarns, hosiery yarns, netting yarns, crochet yarns, tyre cord, etc.

Yarns are also used for

producing certain fabrics like voile, narrow fabrics, cotton sweaters, and

socks, knitted underwear, suiting, bedsheets, curtains, sofa covers, etc.

Reference:

Introduction to Textile Manufacturing- ll by Prof. A.N.Bhorkar

0 Comments