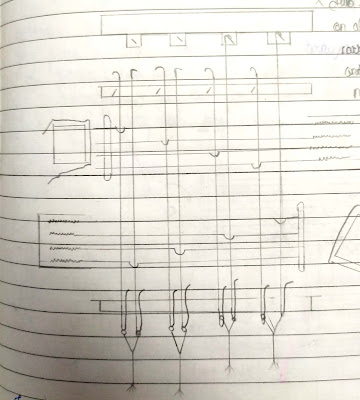

Classification of Jacquard:

|

| Fig- Jacquard Classification |

Single Lift Single Cylinder

|

| Fig- SLSC Jacquard |

In a

single lift single cylinder if 400 ends are working independently then it

requires 400 hooks and 400 needles arranged one per hook. The needles are

arranged in 8 rows and each will have 50 needles. Hooks are connected to do

individual end through nylon cord. One knife is responsible for controlling the

one row of hook. The cylinder carried punched cards. The needles are connected

with the spring at the opposite side to the cylinder. If there is a hole in a

punched card, needle will be able to pass through the hole. It makes selection

of that hook by knife and end is lifted up. If there is a no hole the hook will

not lifted up.

In

SLSC jacquard, if loom speed is 200 PPM the cylinder will turn to 200 times per minute. The knives will move up and

down 200 times per minute. Thus it interfere high loom speed.

Thus,

1.

In 400 end machine, it will have 400 needles and 400 hooks

2.

Cylinder should turn in every pick.

3.

Knives must complete the cycle of rise and fall in every pick.

4.

Bottom closed shed is produced.

Double

Lift Single Cylinder:

|

| Fig- DLSC Jacquard |

For DLSC Jacquard one end is controlled by two hooks, which are again controlled by single needle, to set of knives move up and down in complete phase difference. In the diagram it is shown that the end control by hook D is lifted up and end controlled by hook A is kept down on the first pick. For the second pick, the end controlled by D will remain down because the needle controlling hooks C misses the knife because the paper pattern has blank. The end controlling hook B will be lifted up because hook A will now engage with the knife as needle controlling it, passes through the hole in paper card. In this jacquard if the loom speed is 200 then the cylinder is rotate 200 times a minute but knives will reciprocate 100 times per minute. This is the advantage of DLSC Jacquard.

Advantages:

The

shed produce is semi open shed. It works with the higher speed than SLSC

without increase in wear and tear.

In

the DL jacquard the moving parts work at half the speed of crankshaft.

In

the double lift Jacquard weft is beaten up in the cross shed improving the

cloth cover.

In

the double lift Jacquard rising shed line in balanced by the lower in shed

line.

DL

Jacquard consume less power.

Thus

DLSC has,

1)

If 400 ends, it will have 400 needles and 800 hooks.

2)

Knives rise and falls in the opposite face.

3)

Knives movement repeat after 2 picks.

Double

lift Double Cylinder:

|

| Fig- DLDC Jacquard |

In

DLDC Jack and the number of cylinder rotation and number of reciprocation cycle

of knife is half as compared to SLSC. In this case one end is controlled by two

needles, two hooks. hear all pics are controlled by one cylinder and even picks

by another cylinder. It has got advantage with double lift single cylinder i.e.

the cylinder speed is also half therefore the speed of the Jacquard can be

increased. The total number of card required are split into two sets. It

reduces the weight of card and number of picks per repeat can be increased. It

produces semi open shed and hence all the advantage of double lift single

cylinder. Therefore to control 400 ends it will have 800 needles and 800 hooks.

It has two set of knives rise and fall in opposite face. The knife complete its

cycle over two picks and cylinder turn on the alternate pick.

Springless

Jacquard:

|

| Fig- Springless Jacquard |

The

springless Jacquard is DLDC machine which produce semi-open shed. This Jacquard

do not contains the spring hence the design difficulties arises because of the

spring are eliminated. The set of needles is controlled by two cylinders from

both the sides. Each needle controls the pair of hooks, the hooks are shorter

in length, self spring and made up of high quality spring. Two cylinder one for

odd picks and another for even picks is used. If there is a hole in the card

hooq will engage with knife and if it will be blank, hook will not engage in

the knife.

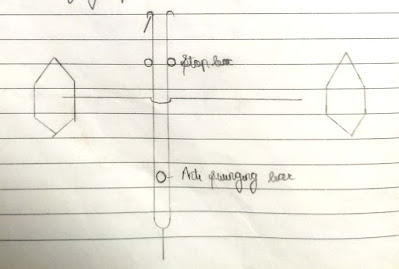

Cross

Border Jacquard:

|

| Fig- Cross Border Jacquard |

Need

of Cross Border Jacquard:-

When weaving the fabrics like Terry towels, chaddars, sarees, tapestries, we need border along the four sides of the fabric. To achieve we need a set of paper cards which will produce the border design. can be achieved by cross-border Jacquard. It is DLSC jacket with extra cylinder for border cards.

Working of Cross Border Jacquard:-

It

has two cylinder which are work alternately. It is DLSC mechanism when the body

cylinder work, Jacquard works in conventional way as DLSC. When the cross

border design is needed, body cylinder is taken out of function and border

cylinder is put in use. The border cylinder has short needle which are spring

loaded. To each needle there is a one suspended rod which is attached to the

main needle controlling hook but the suspended rod is fulcrumed in the middle.

So when border cylinder works if there is a hole the main needle is pushed to

engage hook and knife ,when there is a blank the hook will miss engagement with

the knife.

Coarse

and Fine Pitch Jacquard:

Find

pitch jacquards are originated in France. They are compact and extensively used

for weaving design repeating on large number of shed like silk. The main fine

pitch machine are are Vincenzi and verdol.

|

| Fig- Vincenzi Jacquard |

Vincenzi

Jacquard has each of 40 needle per square inch as agains 14 in coarse pitch.

Standard size of the machine are in multiple of 440 hooks arrange with 16

needles per short row and common sizes are 440, 880, 1326, 17260 and 2640

hooks. It is DLDC producing semi-open shed. It has got 'U' type of hook having

self spring action and thus use of spring in the needle board is avoided the

pattern cylinder is hexagonal. There is two sets of knives.

Verdol

Machine:

Verdol

has 80 needles per square inch and standard size are 48, 896, 1344 and 1792

warp threads in a repeat. This machine

uses indirect method of selection using endless paper pattern. It is always

single cylinder machine of either single lift forming the central shed or

double lift forming open shed.

0 Comments