Classification of Dobby:

INTRODUCTION: -

Dobby is a shedding device

attached to the loom to increase the design capacity. The dobby normally

controls 12 to 24 hold shafts the dobbies are classified as negative or

positive, single lift, double lift, crank driven, cam driven, etc.

The dobby forms a bottom closed,

center closed, semi-open, and open type of shed. The dobby is also classified as

left hand and right hand.

The right-hand dobby is placed at the left-hand side of the left hand. It gets driven from the left-hand

end loom.

The left-hand dobby is one placed

at the right-hand side of the left-hand loom. The left-hand dobby gets its drive from the right

end of the loom.

Difference between tappet and dobby shedding:

|

Tappet Shedding |

Dobby Shedding |

|

Tappet shedding is simple and cheap in construction. |

Dobby shedding is relatively complicated. |

|

Tappets produce simple and basic designs using a

maximum of only eight heald shafts. |

A dobby can produce small motifs using many more

heald shafts up to a maximum of 40. |

|

A tappet loom works efficiently and consumes less

power. |

A dobby loom consumes more power. |

|

A tappet loom can be run at high speed with less

machine vibration. |

A dobby loom cannot be worked at high speed because of

high machine vibration and excessive friction between moving parts. |

|

Tappets are required to be changed for altering the

design gearing on the bottom and counter shafts are to be altered. |

The designs can be modified easily change out is

brought about quickly and does not require any major alternation |

|

The number of heald shafts used and picks/repeat

cannot be changed for a given set of tappets. |

The number of healds and picks/repeats can be easily

altered. |

|

In a tappet, the shedding dwell period is maintained for

the safe passage of the shuttle. |

In swing lever dobbies there is no dwell period. In

a cam dobby, a dwell is maintained. |

Climax Dobby

The Climax Dobby is a double-acting machine controlled from the bottom shaft, it forms the open shade. The lifting of heald is done by the lifting of jacks. The healds are lowered because of springs used on the bottom side. It has 2 jacks. Dobby runs at half the speed. In the right-hand dobby, the cylinder rotates in a clockwise direction. In the left-hand Dobby, the cylinder rotates in an anticlockwise direction.

Working

Dobby gets its drive from the bottom shaft through a connecting rod. The T-lever gets oscillation and thereby knives move forward and backward in the framing machine slot. When the knives are towards the set of hooks selection of engagement hook and knife is made feller. The feelers are activated because of wooden pegs. when the hooks and knives are engaged, then the hook is pulled, while the other hook and the lever rest on the stop bar. now the heald is lifted up.

Cycle of lifting of healed into Climax Dobby:

A-The Healds shaft

remains down no selection has taken place.

knives K1 and K2 are about to move from extreme positions.

B-Heald is down

and the hook is not engaged with the knife on the second pick.

C-It represents the engagement of the hook and knives are about

to pull the hook to lift the shed.

D-Heald is lifted up on the pick.

E-The heald is again lifted up on the next pick because of the engagement of hook and knife.

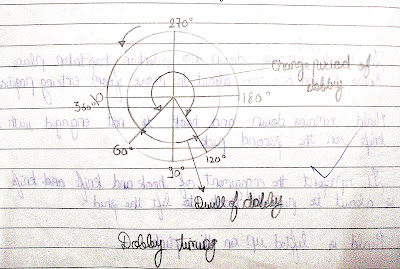

Timing and setting of Climax Dobby:

1-At 270 degrees The heald shaft is leveled, and knives are in the midway position.

2-The T- lever is horizontal. At 60 to 120 degrees is the dwell Period of

the dobby.

- Heald is stationery

- shed shed is open

3-At 90

degrees, one arm of the t— lever is outside and another is

inside.

4-The bottom shaft is at the top or on the bottom center

At 120 To 360 degrees To 60 degrees is the change period of the heald shaft.

Settings:

1- The driving rod connecting to the crank attached to

the bottom shaft of the loop and T-lever must be set to the appropriate

length. If the rod is too short or

long, one set of the hooks will travel more distance than the other.

2- The length of the driving rod is adjusted such that T-Lever is horizontal when the crank attached to the

bottom shaft is in a horizontal plane either in the front or back of rotary its

stroke.

3- Crank and T-lever are kept in the horizontal position and now two knives are Adjusted by draw bolts so that they are equidistant from their slots. The pattern cylinder is

rotated by a ratchet wheel. The cylinder is

rotated by 1/8th revolution for every 2

picks. the cylinder is held steady by a flat steadied star wheel. The Pawl regulates through the star wheel. The

T-lever is lifting knives in are

extreme position there should be a

quarter-inch clearance between the tip

of the pawl and the teeth of the

cylinder ratchet.

For right-hand Dobby visible outermost feeler which operates the bottom drawer hook, the pattern

cylinder rotates clockwise.

In the left-hand Dobby,

the first feeler is a straight

feeler that acts on the top hook.

In pegging, the upper row of holes in the lug represents the first pick.

Cross Border Fabrics:

Many fabrics need a border in the warp as well as in the weft way. for creating the weft way border design. The number of wooden legs required is

high. so to create a border design, a special cross-border Dobby is used. the fabrics that need the cross border are

sarees, carpets, Chadar, tapestries,

handkerchiefs, and table covers.

Cross border Dobby

Cross-border Dobby is used when two different weaves are

required to be woven using the same number of healds.

Cross-border Dobby eliminates the high number of wooden legs

that are required in normal dobbies.

Types of cross-border dobbies:

1- Two cylinder

cross border Dobby

2- Three cylinder cross border Dobby

Dobby Faults:

The common problem in the dobby is Jack missing. The

heald shaft is not lifted when required and the weft floats across the warp end

giving rise to the fabric effect called stitching.

Stitching is sometimes caused by shuttle flying. Warp

thread breaks occur because of shuttle fly causing a major fabric defect.

The causes of Jack's missing (Heald not lifted) are:

1) Bent wooden peg in a lag.

2) The wooden peg is worn out due to frequent use.

3) The spacing between the lag should be uniform and the cylinder should be perpendicularly positioned below the feeler. if

the lags are not spaced properly more feelers may be lifted causing the lifting of

improper jack.

4) The pattern barrel in which the wooden lag rotates should

not move laterally.

5) The needle operating hook may get stuck and the jack is

missed, good oiling is necessary.

6) The wooden peg will be broken and therefore jack is

missed.

7) The hook may come off from the knife in the middle of the stroke, causing a missing jack.

Ruti Cam Dobby:-

The ruti cam dobby is negative in action i.e. the heald are lowered because of the spring in this dobby. The knives are pushed forward by the pair of cams. The knife will come back and always be in contact with the cams because of the spring. Here dwell of about 1/3 pic is achieved. The selection of the hooks is made of paper patterns instead of wooden pegs.

Positive Cam Dobby:-

The positive cam dobby is called positive because lifting and lowering of the heald is made positively. The dobby has a cam that will give oscillation to the griffel and returning bar through the lever i.e. when the griffel is engaged with the hook it will pull one side of the bulk and at the same time return the bar to push the other side of the bulk. Suppose heald is to be kept down on the next pick, the bottom hook will not be engaged in the griffel, it is looked in the locking bar and thus engaged in the griffel, it is looked in the locking bar and thus the other end of the bulk will not move even the upper return bar pushes to the bulk towards the stop and heald will be down. in short, it returns the bar stop and locking bar together making the dobby positive along with grooved cam.

3 Comments

Great post indeed.

ReplyDeleteSuch a detailed Study of Dobby. Thanks for Sharing.

ReplyDeleteVery good content on dobby shedding sir

ReplyDelete