The application of textile in

technical and functional purpose is known as technical textile. It is not used

for aesthetic purposes rather than function that makes it different from other

textiles. Sometimes it is called by smart textile depending on application that

can sense and react to environmental stimuli, which may be mechanical, thermal,

chemical, biological and magnetic amongst others (TAO 2001) These are made with

variety of fibers, filaments, yarns depending on the goal of end product.

Sometimes natural and sometimes synthetic

whatever is more suitable for specific

purpose. The most important thing is technical textile can maintain several

things that traditional textiles can not. However , technical textile does not

mean only yarn –fabric, it can be a dye particle also which is used in

technical purpose.

Nowadays, we are not talking merely of fabrics and textiles imparting information; We are talking about much more. Nor are we referring to fabrics that may have multifunctionl purposes, such as fashion and environmental protection, or rainwear, or those fabrics providing resistance to a plethora of threats, such as ballistic, chemical and flame protection. we are talking here about materials or structures that sense and react to environmental stimuli, such as those from mechanical, thermal, chemical, magnetic or others. We are talking ‘smart’ and ‘active’ systems. We are talking about the true merger of the textile and information industries. Smart textiles’ are made possible due to advances in many technologies.

Technical textile composition by region:

|

COUNTRY |

PERCENTAGE |

|

USA |

23% |

|

WESTERN EUROPE |

22% |

|

CHINA |

13% |

|

JAPAN |

7% |

|

INDIA |

3% |

|

REST OF THE WORLD |

32% |

Chart -1: technical

textile composition by area

Fiber wise

composition of technical textile:

The use of fibers in

technical textile are given below:

|

FIBER |

PERCENTAGE |

|

Polyester

|

25% |

|

Polyolefin

|

25% |

|

Glass |

15% |

|

Jute

,coir |

14% |

|

Cotton

|

7% |

|

Viscose

|

3% |

|

Other

cellulosic fiber |

3% |

|

Polyamide |

7% |

|

Aramid

,carbon and others |

1% |

Chart -2: Fiber wise

composition of technical textile

There are, naturally,

many more applications for ‘smart’ textiles than those applied to military

personnel, or civilian police, firemen, and emergency responders. Mountain

climbers, sports personnel, businessmen with built-in wearable microcomputers,

and medical personnel will all benefit from this revolution in textiles.

Promotion of technology for

textiles:

The nature is the main inspiration in order to create our clothing materials

with higher levels of functions and smartness. The development of microfibres

is a very good example, starting from studying and mimicking silk first, then

creating finer and, in many ways, better fibres. However, up to now,most

textiles and clothing have been lifeless. It would be wonderful to have clothing

like our skin, which is a layer of smart material. The skin has sensors which

can detect pressure, pain, temperature, etc. Together with our brain, it can

function intelligently with environmental stimuli.

Fibres used in technical textile:

There are both natural and synthetic fibres used in technical purpose depending on end purpose. Here is some top applied fibres:

- Polyethylene

- Polyester

- Nylon

- Carbon

- Polypropylene

- Aramid

- Metal

- Glass

- Ceramic

- Nano fibres

- Piezoelectric fibres etc.

Ultimate areas of technical textiles:

The leading international trade exhibition

for technical textiles – Techtextil (http://

techtextil.messefrankfurt.com/frankfurt/en/besucher/willkommen.html) – defines

11 main application areas.The area of application of technical textile which paves

the way for future textile are broadly discussed below:

1. Protech – Innovations in personal and property protection. To apply textile technology in protective fabric( protective textiles) for increasing work safety ,normally said as PPE(Personal protective equipment).these are used in:

- Water and wind resistant clothing

- Heat and flame resistant clothing

- Antimicrobial clothing

- Radiant heat protective clothing

- Chemicals protective clothing

- Fire fighter suits

- Biohazard Survival Suit

- Bomb Disposal Suit

- Environment Suit

- Blast suits

- Extreme Environmental Clothing

- Army Combat Shirt

- High-visibility (HV) Clothing

- Anti-Static Clothing

- Industrial Work wear;

- Lifejacket (Personal Flotation Device)

- Motorcycle Personal Protective Clothing

- NBC (Nuclear, Biological, Chemical

- Clean room Suit

- Arc Flash Protection Clothing

- Racing (Race Car Driver’s) Suit

- Flight Suit

Figure-3: Structure of water proof breathable garment, fireproof garment,

spacesuit and bulletproof vast.

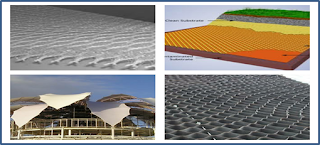

2.Buildtech –To applys textile

technology in constraction work(geo textiles) such as road construction, dam

construction, soil sealing, drainage system etc. Sometimes it is thought as

construction textiles.Textile products for membrane construction, lightweight

and solid structures, earthworks, hydraulic engineering, and road construction.

Nowadays we are most focused in more sunlight, greener, high performance, cost

saving and sustainable structure.To fulfill that requirements textile play a

fundamental role.Due to special properties like high strength ,modulus,

elongation, flexibility etc textile is used in civil engineering.

Another term is Geotextile which is

used in contact with soil and other materials in geotechnical and civil

engineering. Any permeable textile material used for filtration, drainage,

separation, reinforcement and stabilization purpose as an integral part of

civil engineering structures of earth, rock,other constructional materials.

Some fibres used in geo textiles are : Ramie ,Jute ,Coir ,Polyester ,Polyamides ,Aramid ,Polyethylene ,Polyvinyl chloride,HDPE,PET

3. Clothtech – To apply textile

technology in clothing applications like Innovations in shoe and clothing

manufacture. Can you think what would happen if your dress can recognize your

body health and your position ?However, wearable technology is making headlines

nowadays: smart watches and health trackers are so 2014;wearable fashion tech is

all the range. If you want to get in on the wearable trend ,forget about

getting the latest apple watch. Smart clothing is the next wave of disruptive

technology that is woven into our daily fabrics-literally so.

The interest in wearable fashion tech

goes beyond wrist-worn accessories.Like superman who gains superpower from his

magic cape,smart garments can empower us all around to give us superpower .The

same chips and sensors that powered smartwatches can be embedded in

fabrics,which is what made the garmentssmart .Because they are in close contact

with our skin-the largestorgan of body.the embedded smart tags and sensors are

getting thinner and more invisible.Recently, smart clothing makers such as

Primo 1D have developed e-thread with ultra high frequency RFID directly woven

into the fabrics.

Not surprisingly, many smart clothes

are focused on monitoring and improving sports performance. For instance, smart

shirts and shorts have the capacity to accurately track real time health data

such as heart rate ,movement, respiration, breathing etc.

Smart sleep wear helps a person to

sleep properly .The garment has bioceramic particles woven into its fabric, which

helps to absorb infrared weave lengths and helps to reduce inflammation while

an athlete is sleeping.

Figure-5:

Wearable technology/Cloth Tech

4. Hometech – To apply textile

technology in domestic environment such as carpeting ,decoration, wall

coverings , curtains,cuhion covers,pillowcases blanket ,Innovations in the

manufacture of furniture, upholstery, floor coverings, and carpets etc.

However, the global home textile market

demand is expected to reach 160+ billion dollars by 2025.

The most recent research in home

textile is antibacterial coating on fabric which helps to keep safe from germs.

Mainly on bed sheet ,towel, pillow cover which have much possibility of getting attack of bacteria or

germs. For this purpose ,the fabric is treated with antibacterial agents .As a

result , the antimicrobial agent chemically bind on the surface of treated

fabric and do not detach from surface by its own. Microbes are killed by agent

when become in contact with treated

fabric.

Moreover ,a new research finds

that towel which changes its color

itself when it get dirt and affected by bacteria.

Figure-6:

technology in home textile

5. Sportech – To apply of textile technology in sport

instruments(sports textiles) such as

shoes, special dressup, sport bags, climbing, angling, cycling etc. Foe fulfilling this purpose ,textile must

have some properties .such as: comport ability, easy to wear, easy handling ,high

electrical conductivity, light weight, wicking properties, elastic properties,

much strength etc.

Some area of application of sport textiles are swimming costume, artificial turfs, sleeping bags ,ballooning and parachute fabrics ,sports footwear etc.

6. Medtech – To applytextile

technology in medical life(medical textiles) such as first aid, clinical,

hygienic purpose. Medical textiles are an important part of the large variety of

technical textile products, ranging from high volume disposable products for

baby dispwes, feminine hygiene, specialized and high-value textile products for

use in blood filtration ,surgical sutures, prostheses and scaffolds for new

tissue growth.

The most innovative use of textile in medical is artificial body tissue ,joint, ligament and organ(liver, kidney, lungs, heart, bone, etc).

Here some more applications of medical textile. such as:

- Skin closure tape

- Allograft skin tissue processing

- Urinary incontinence sling

- Pacemaker lead anchor

The recent research has created flexible yarn from human skin cells, which can be knitted ,crocheted or weaved into unique patterns for medical purpose. The threads can be used in surgery to help treat animals and humans. Scientists say it will not be rejected by the immune system of the recipient. Cells called fibroblasts from an animal can be used to make sheets of skins in a lab. Already the French researchers have used the material in operation on animals and say it could be used to make 'Human textiles' for tissue grafts or organ repair in the furture.

According to CNN health, a group of researchers has come up with a unique form of yarn made up of human skin cells that could soon replace conventional sutures in surgical procedures.

Figure-8: Yarn made from human cells used in human textiles

7. Agrotech – To apply textile

products for agriculture,aquaculture,forestry, horticulture, and landscape

gardening with the aim of improving yield, efficiency and profitability.Agrotextile

include use of plant net,sunscreen,bird protection net,ground cover,mulch

mat,monofil net,anti-hailstone net,harvesting net,wind shield,root ball

net,insect meshes,weed control gabric,net and ground cover made of polyolefin

as well as jute,wool fibres. Moreover, crop production, cattle

breeding,regulate nutrient level intake of plants and assist the process.

It can be used in fishing industry in

the form of nets,ropes and lines,to prevent the soil from drying out increase

crop yield, to protect farmer from harmful pesticides, to improve product

quality, to save energy in field as possible as , to thermal protection, to

prevent insect contact with food or crop and to reduce workers and work load.

Some properties that is required for

agrotextile product are: tensile strength. Withstands solar radiation,

withstands uv radiation, bio degradability, abrasion resistance,high potential

to retain water, protection property, resistance to microorganism, lightweight

etc.

8. Oeko-tex – To appliy textile in

environmental protection (ecological protection textile) such as preventing

soil erosion ,water pollution, waste recycling etc. It Is also called

ecological textile.

It is used in the landfill waste management which refers to use of geo-systhetic products to secure landfills against leakage of municipal or hazardous waste. It can be used in the secondary protection in chemical /oil industries(ground covers and like around processes tanks for secondary containment). Floor sealing erosion protection, air cleaning, prevention of water pollution, water cleaning, waste treatment, despositing area construction, production extraction ,domestic water sewerage plants.

Figure-10:

Textile in environment protection

Some eco friendly textile fibers are:

- Organic cotton, organic wool, organic silk, hemp

- Man made soya bean, Lyocell;

- Recycled cotton, recycled wool

- Naturally colored cotton

9. Mobiltech –To apply textiles for ship and aerospace construction as well as automotive, railway,space travel and many more high tech –high performance application.

Automobile is the largest area of that

which controls followings: seats, seat covers, seat belts, air bag, door

casings, parcel shelves, dashboard, knee air bag, sun visors, luggage nettings,

carpets, air filters, oil filters, battery separator, hood liners etc. Moreover

,nylon tyre cord, helmets, airline disposables are also part of mobiltech.

The most recent use is in the construction of car and aircraft material with carbon fibre composite. Because of carbon fibre having light weight, high tensile strength, high chemical resistance, high stiffness,EM transparent, low thermal expansion and low weight properties. A carbon fibre has a lot of good properties which makes it a very good material for different industries to use.Here is on right a graph showing the stiffness/strength of a carbon fibre with respect to its density.

10. Indutech – To apply textile

technology in chemical and electrical applications(industrial textiles)such as

filtration, seals, plasma screes, melting process ,Products for mechanical

engineering and for chemical and electrical industries etc. specific products

under indutech include filters, wipes, felts and three dimensional textile

products. The textile includes ropes, which occupy the prime position in the

market and are used in shipping, ports, oil

rigs, and defense areas. Computer printer ribbons and computer printer

refills are indutech products that are made up of acrylic butadiene styrene and

are expected to grow rapidly in the market due to the excessive rate of

computerization. Market for wet filtration filter cloth,made of iindutech woven

and non woven materials is also expected to increase gradually.

Figure-13: Technical textile in industry

11. Packtech – Innovations in packaging, covering, and transportation. To ensure scratch free and safe handling of sensitive articles textile partitioned boxes are an ideal option.

Some products of packtech are:

- Woven sacks of polyolefin

- FIBC (flexible intermediate bulk containers)

- Leno bags

- Wrapping fabric

- Kute hessain and sacks

- Tea bags

- Soft luggage products

The future of technical textiles includes a much wider economic sphere of activity than only the direct manufacturing and processing of textiles: Technical and performance textiles represent an emerging generation of products combining the latest developments in advanced flexible materials with advances in computing and communications technology, biomaterials, nanotechnology, and novel process technologies.

Many exciting applications have been demonstrated worldwide. Extended from the space programme, heat generating/storing fibres/fabrics have now been used in skiwear, shoes, sports helmets and insulation devices. Textile fabrics and composites integrated with optical fibre sensors have been used to monitor the health of major bridges and buildings. From decades ,the area of textile is increasing and the area of research also spreading. Some area of future reseach for technological textile or smart textile are:

Figure-14:

The future fabric; will be able to change own colour and design

- At first the consideration about water will be thought. Because 1 kg cotton production costs 29,000 liters of water not to mention the chemicals used for farming ,cleaning, and dyeing of fabrics. That is why is it no longer late to produce colourful cotton by genetic modification.

- The yarn will be smart yarn by which all the function of a smart watch can be done.

- To colour the synthetic textile materials, a new process of dyeing named spray dyeing will be developed soon which will reduce the amount of dye during dyeing.

- Digital printing methods have been developed to produce jeans wear that look worn instead of the dyeing and stone washing of conventional manufacturing.

- Smart textiles for smart home control and enriching future wireless sensor network data.

However last but not least, technical

textile is going to be a blessing for our future life and something special is

coming which will take us beyond every limites.

References :

1. Xiaoming Tao, Smart fibres,

fabrics and clothing, Cambridge, England,2001.

2. A Richard Horrocks and Subhash C.

Anand, Handbook of technical Textiles,Volume 1: Technical Textile Processes,

Kidlington, UK,2016.

3. A. R. Horrocks and S. C. Anand ,Handbook

of technical textiles, volume 2, UK,2016.

4. J W S Hearle, High peroformance

fibres, USA,2001.

5. Gang Sun, Antimicrobial

textiles. California,2016.

6. Yimin Qin, Medical textile

materials, UK,2015.

7. Olivia ojuroye, Russel torah, Steve

beeby and Adriana wilde. Smart textiles for smart home control ;(oct

2016)

8. Jane McCann, David Bryson, Smart

clothes and wearable technology,Elsevier,2009.

9. Paolo Bonato, Advances in wearable

technology and applications in physical medicine and rehabilation, Journal

of neuro engineering and rehabilation 2(1),1-4,2005.

10. Ratnakar adhikari and Chatrini

weeratunge, Textile and clothing in south asis: Current statuas and future

potential, South Asia Economic Journal 8(2),171-203,2007.

11. Majid montazer and Esfandiar

pakdel, Functionality of nano titanium dioxide on textiles with future

aspects: Focus on wool, Journal of photochemistry and photobiology

C:Photochemistry reviews 12(4),293-303,2011.

12. Olivia Ojuroye, Russel Torah,

Steve Beeby and adrina Wilde, Smart textiles for smart home control and

enriching future wireless sensor network data, Sensors for everyday

life,159-183,2017.

13.NL Belkin, Textiles as aseptic

barriers: the past, present and future, Medical instrumentation 14(4)

233-236,1980.

1 Comments

This is a fantastic and informative blog—I really appreciated the clear and detailed explanation.

ReplyDeleteAt Disha Jute, we share the same dedication to producing high-quality jumbo bags (FIBC bags) for industrial and bulk packaging needs.

Looking forward to reading more of your valuable posts!