Test

Methods of Geotextiles

Susmita Jagadale, Rahul

Prasad

Department of Textile Chemistry

DKTE Engineering College ,Icchalkaranji,

India

Technical textiles

have the extreme range of products. but so many researchers are still carried

out. Among various types of technical

textiles, geotextiles possess very important class due to its versatile

applications in roads, automobiles, dams and constructions industries.

Geotextiles are the permeable textile materials which mainly used for filtration,

drainage, separation, reinforcement and stabilization purposes. Geotextiles is

the fastest growing industry and a promising field of technical textiles. Due

to that need different properties of geotextiles plays very important role. In

our research paper we highlight that need and also we explain that various live

test methods so that proper selection of material is carried out.

Keywords: Technical

textiles, geotextiles, non-woven, reinforcement.

INTRODUCTION:

In 1972, geotextiles were largely

untested, and the site was set up as an accelerated field test to determine the

comparative performances of several fabrics for use as a geotextiles.

As we know

geotextile, geo, means earth and the ‘textile’ means fabric. Therefore,

according to the definition of ASTM 4439, the geotextile is defined as follows:

"A permeable geosynthetic comprised solely of textiles. Geotextiles are

used with foundation, soil, rock, earth, or any other geotechnical

engineering-related material as an integral part of human-made project,

structure, or system."

Functions of

geotextiles:

Separation:

Geotextiles will prevent two soil layers of different particle sizes from

mixing with each other, as is illustrated the image below.

Drainage: Geotextiles

will efficiently collect superfluous water from structures, such as rainwater

or surplus water, from the soil and discharge it.

Filtration:

Geotextiles are an ideal interface for reverse filtration in the soil adjacent

to the geotextile. In all soils water allows fine particles to be moved. Part

of these particles will be halted at the filter interface; some will be halted

within the filter itself while the rest will pass into the drain. The complex

needle-punched structure of the geotextile enables the retention of fine

particles without reducing the permeability of the drain.

Reinforcement: Heavy

geotextiles can be used to reinforce earth structures by means of fill

materials. Thanks to their high soil fabric friction coefficient and high

tensile strength, they are an ideal reinforcement solution.

Protection:

Geotextiles are an ideal protection from erosion of earth embankments by wave

action, currents or repeated drawdown. A layer of geotextiles can be placed so

as to prevent leaching of fine material. They can be used for rock beaching or

as mattress structures. They can even easily be placed under water.

THE NEED TO GET IT

RIGHT:

It may be argued that geotextiles are such

a small part of a civil engineering project as to be financially insignificant

and therefore not worth spending much

time focusing on developing specs or seeking supply quotations. But the implications to long-term performance

of a civil engineering structure are far greater than the initial cost of

purchase of the geotextile. The failure of a roadway due to rupture of a geotextile

or the erosion of a dam wall due to piping of embankment material through a

geotextile filter are examples that clearly show the enormous potential

financial impact that failure of a geotextile may have on a project.

Having many different specs in various

States causes manufacturers to produce a host of different products

unnecessarily. Setting uniform,

consistent specs brings economies by allowing manufacturers to focus on

producing and stocking fewer grades.

REINFORCEMENT:

The key difference between stabilization and

reinforcement is that stabilization is accomplished by providing for drainage

of water from the unstable soil, while in reinforcement the strength

characteristics (stress–strain) of the geotextile provide added strength to the

whole system. Another difference is that in stabilization the geotextile is

placed on or around the area being stabilized and thereby also acts as a

separator, whereas in the reinforcement application the geotextile is placed

within the material being reinforced. This is in line with reinforcement

concepts in concrete and other materials.

- Concrete is used in innovative designs because of its many valuable properties such as high compressive strength, stiffness, low thermal, electrical conductivity, and low combustibility.

- However concrete is brittle, weak and develops cracks during curing

- The recent development of Fiber reinforcement in Concrete in various fields has provided a strong technical base for improving these deficiencies.

Why the Reinforcement of the concrete comes ?

- Concrete plays important role in Construction line which is India’s second largest field in terms of Economy. Too improve the quality of construction we are enforcing the concrete with the textile fibers. To improve the some properties of that concrete.

How it come to know ?

- Human being is motivated for fiber reinforcement from nature

- Hornero bird native to South America

builds nests out of straw and

Clay.

- Roman Colosseum built

in 80 AD. stands strong This

structure was built with horse hair as reinforced fibers and the structure is a

glittering example of strength and durability.

- Tipu Sultan’s palace at Srirangpattnam which still stands as it is after

centuries was reinforced with Sheep’s wool.

- A Pueblo house built in 1540 with straw reinforcement is the oldest house in USA.

- The good example of it is we see mud wall in villages with straw reinforcement.

So where do we see cracks in Concrete All around us?

- Parking area

- Industrial flooring

- Concrete terrace

Mechanics involved in

fiber operation:

- Damage of fiber matrix

- Fiber/matrix debonding

- Fiber bridging

- Fiber failure

- Fiber Pull-Out

Factors affecting fiber reinforcement in concrete:

- Effect of Fiber Length

- Effect of fiber volume fraction

- Effect of fiber cross sectional shape Variation in the

material

- Variation caused by the test method

- Environment

- Type of instrument & its accessories

- Conditions of testing such as speed, pressure and duration

Objective of fiber reinforcement in concrete :

- Based on literature survey following objectives were finalized

- To Prepare fiber reinforced concrete with natural and synthetic fibers in different proportions

- To study effect of fiber type and fiber proportion on the characteristics of concrete.

Methodology:

- Mixing of fibers

- Preparation of Fiber Reinforced concrete blocks

- Testing of Fiber Reinforced concrete Blocks

Experimental Work:

- Polyester fibers, Polypropylene fibers, Banana fibers, Coir fibers is taken for test

- Fibers were dispersed in water by continuous stirring. This water in which fibers were dispersed was used for forming the concrete.

- The proportion of fibers in concrete used was 0.25 % - 1 % on weight of cement

Preparation of Moulds and Testing of Fiber

Reinforced Concrete:

- Compressive Strength

- Tensile Strength

- Moisture Absorption Test

- Slump Test

- Setting Time of concrete

Tensile Splitting Strength:

- As per ASTM C 496 standard Tensile splitting strength test was performed using cylindrical specimen.

- In determining the modulus of rupture by a beam specimen the upper, part of the specimen is in compression while the lower part is under tension, therefore it gives a better idea about the tensile strength of concrete.

Compressive

Strength

- As per TS EN 12390-3 Standard compressive strength test was performed.

- The most important property of concrete is the compressive strength which was determined by loading the molded and cured specimens.

- The testing machine used had sufficient capacity which provided the required rate of loading.

Moisture Absorption:

- As per ASTM C 140 moisture absorption of concrete was performed.

- The concrete cube was kept in oven; so that the moisture present in the concrete cube will evaporate then the oven dried cube were kept in water for 24 hours.

- Then the water absorbed by concrete was found by weighing the block.

- Amount of moisture in concrete, was known as the moisture content and was expressed as a percentage on the mass of the concrete.

Slump Test (Workability):

- As per ASTM C 143 standard test method for slump of concrete was carried out.

- Slump test was performed to check the workability and consistency of the fresh concrete with fibers.

Setting Time:

- As per ASTM 403 standard test method for setting time of concrete was carried out.

- This test was done using Vicat’s needle apparatus.

- In this test a needle was tried to penetrate on a concrete mould.

- The time at which needle ceases to penetrate gives the Setting time.

RESULTS:

|

Effect of fiber type and proportion on

Compressive Strength of concrete

|

|

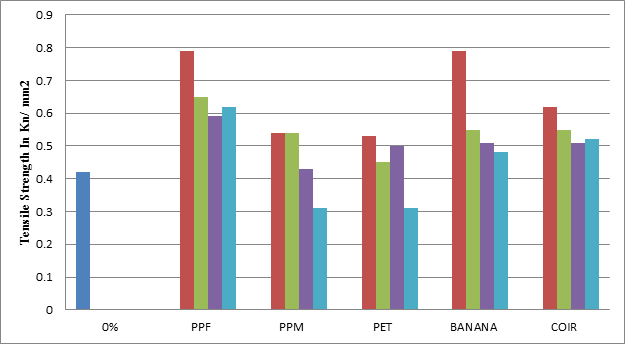

| Effect of fiber type and proportion on Tensile Strength of concrete |

|

| Effect of fiber type and proportion on moisture absorption of concrete |

|

Effect of fiber type and proportion on Slump (Workability of Concrete)

|

|

Effect of fiber type and proportion on Setting time

|

CONCLUSIONS

- Test methods are a means to understand the product

- Test results give a true picture of the product

- Test results are dependable when conducted exactly as per the standard test methods

- Compressive strength of fiber reinforced concrete has improved significantly, especially in case of Polypropylene fibrillated and banana fiber at 0.25%.

- There is no effect on Moisture absorbing property of concrete reinforced with polypropylene fibers at all four levels of fiber volume fraction,

- Polyester, banana fiber, coir there is significant effect on moisture absorbing, also with polyester and both the natural fibers the moisture absorbing has reduced significantly.

- Workability

for all the fibers is satisfactory at low fiber volume fraction, but in case of

banana & coir at 1% workability is poor.

- Setting time

is not affected for PP fibers at

all levels of fiber volume fraction, but for Polyester, banana fiber, coir

there is significant effect on setting time.

- Finally it can be concluded that fibrillated polypropylene fiber gives best results in terms of strength and has no adverse effect on moisture absorbency So if proper fiber reinforcement techniques used one can improve the life of concrete structures.

REFERENCES:

- Kaniraj, S. R. & Rao,G. V.(1994) Trends in the use of geotextiles in India,Geotextiles and Geomembranes,13(6-7):389 402.Doi:https://doi.org/10.1016/0266-1144(94)90004-

- Sarsby, W. R. (2007).Geosynthetics in civil engineering. Woodhead Publishing, Abington, Cambridge.

- Ingold, T. S. (2013). Geotextiles and Geomembranes Handbook, Elsevier, Amsterdam, The Netherlands.

- Samrat Mukopadhyay, Raul Fangueiro, “Banana Fibers- Variability and Fracture Behavior”, Portugal, Journal of Engineering Fiber & Fabrics Vol 3 Issue 2, August 08 .

- F.Pacheco Torgal1, Said Jalali “Vegetable Fibre Reinforced Concrete Composites: A Review” 1C-TAC Research Unit, University of Minho, , Portugal

- “Secondary Reinforcement Fiber for Concrete”, Buckeye Building Fibers Tillman Memphis, www.ultrafiber500.com

- Grand View Research Forecasts Global Geotextiles Market (https://www.estormwater.com/grandview-research-forecasts-global-geotextiles-market) (access date: 13/10/2017)

- M.Y. Gudiyawar and A. V. Mahajan, “Application of Fibers in Fiber Reinforced Concrete” www.fibre2fashion.com

- M. A. Erki, S. H. Rizkalla, “Fiber reinforcement polymer Reinforcement for concrete” , Concrete international Journal, June 1993, Page no 48.

- Indrajit Patel and C D Modhera , Study Basic properties of fibers reinforced high volume fly ash concrete” Journal of Engineering research and studies.

- H. Jia and C. Vipulanandan, “Nondestructive Evaluation Of Fiber Reinforced Polyester Polymer Concrete” , Department of Civil and Environmental Engineering University of Houston, Houston

- Bruce Perry, “Effective use of Polypropylene fibers in concrete” , Engineering Service group seminar November, 2004.

- http://www.ril.com/html/business/recron_3s.html

- http://en.wikipedia.org/wiki/Fiber-reinforced_concrete

- Journal of Scientific and Engineering Research

36 Comments

Nice project ....

ReplyDeleteBest of luck

Thanks....

DeleteWell explained

ReplyDeleteIt's nice information.... covered all points which is very much important to describe above topic....

ReplyDeleteNice project

ReplyDeleteBest of luck

It's is nice information of testing methods geotextile

ReplyDeleteExcellent project

ReplyDeleteKeep it up guy's

ReplyDeleteBest Luck

ReplyDeletePicture maks the concepts clear results were good.

ReplyDeleteUseful information 👍💯

ReplyDeleteUr the best Brother 🤙

ReplyDeleteKeep it up 🤟

Good..

ReplyDeleteVery useful information

ReplyDeleteBest luck

Nice bro

ReplyDeleteNice one...😊👍

ReplyDeleteNice project

ReplyDeleteBest of luck

Best of luck

ReplyDelete

ReplyDeleteThis project all information is give by the testing methods geotextile

Thnak you for give formation

👍

Best of luck

Nice concept

ReplyDeleteWell Thought

ReplyDeleteGood content

ReplyDeleteNice one

ReplyDeleteNice one

ReplyDeleteBest luck nice one

ReplyDeleteThanks....🙏

Delete👍This is a great project, and still doing something new, good luck with your new journey 👌👌

ReplyDeleteUseful Information

ReplyDeleteGood description 👍

ReplyDeleteGood Attempt..

ReplyDeleteGo For it..

Learn From it applies in your industrial career point of view.. as well as your day today Life ..👍👍💫

Written good way.

ReplyDeleteThe points are in sequence.

Got something new to learn

Thanks....🙏🙏🙏

DeleteSequence of the data in paper is really good.... Keep it up.... Because it helpful for us.....

ReplyDeleteVery nice Attempt . Keep it up

ReplyDeleteGreat attempt.. keep it up bro 🤘

ReplyDeleteThanks for the support......🙏

ReplyDeleteNew comments are not allowed.