Test

Methods of Geotextiles

Saurabh Deshmukh

Department of Textile

Technology

Veermata Jijabai Technological Institute, Mumbai,India

Geotextiles are thin & strong membrane fabric which is used to

reinforce soil & prevent from damage. It is mostly used for

filtration and separation in the road constructions. Geotextile are ideal materials used for Construction

& infrastructure like roads, buildings, dams and many more.why need of

testing to geotextile material? Because, In order to determine if a geotextile

material is suitable for a particular application it must undergo appropriate

mechanical testing procedures. The most common forces a geotextile experiences

during its application are tensile and puncture. The most common geotextile

testing methods are wide widthtensile testing, puncture and puncture resistance

testing, and tensile grab testing. Geotextile test specimens are generally simple to make

as they are usually just squares or rectangles cut straight from the material.

Depending on the test that will be performed on it the sample will be somewhere

between two to eight inches wide and four to eight inches long. Geotextiles

come in three basic forms: woven, punched, and heat bonded. and heat

bonded. The most common materials to make geotextiles are polypropylene and

polyester.

Keywords-Filter

fabric, testing standards, scope of accreditation, fibres ,yarn ,fabric

,terminology, significance ,sampling,conditioning and test methods

Geotextiles

are a polymers & synthetic made from textile materials named as polyester.

The Geotextiles are effectively successful materials to improve road quality.

It is divided into following types:

- Geotextile of Woven Fabrics

- Non-woven Fabrics

- Knitted Fabrics

Geotextiles are a permeable geosynthetic comprised solely of

textiles. Geotextile materials prevent the erosion of earth and similar

substances after the area has been altered due to construction usually

pertaining to civil engineering applications such as roads, pavement, bridges,

embankments and retaining walls. They allow the passage of water but not soil

and other materials.

Products

are tested for the following reasons. Products are tested for the following

reasons.

- Quality assurance and control

- Quality assurance and control

- Setting and maintaining performance standards

- Investigation of complaints

- Product developments and research

Testing

can be classified into two categories:

- Quality testing

- Performance assessment

When

to test geotextile? For any project for any civil engineering project the

design engineer must check the required specifications of geotextile material

without knowing proper specification it is very difficult to select correct

geotextile for any specific project. it is important to get the material tested

from an independent laboratory, to get correct picture. Because after using

geotextile if it fails then not only the geotextile will fail total structure

will be collapsed. That is useful to check

capabilities of textiles that will be helpful for Roads & highways. Some

testing such as Direct shear test, Compressive creep properties, Tensile Creep

and Creep Rupture Behavior, Resistance to perforation (Cone drop test),

Trapezoid tearing strength, Grab tensile strength and more.

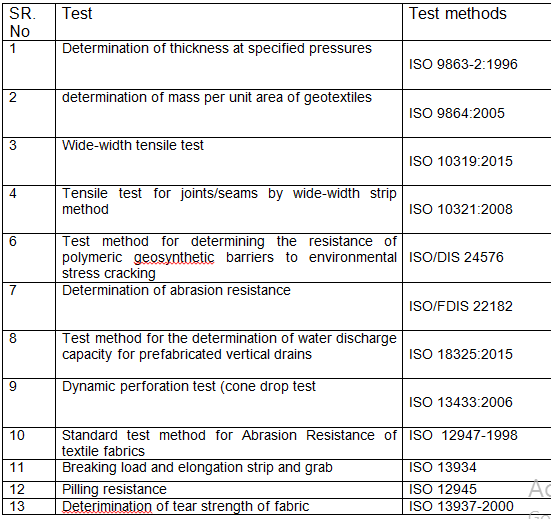

What based on test are perform?

Testing should be done by some

methods or also known as testing standards. That is some standard set by

laboratory, institute or research centre that is given below :

- ASTM - American Society for Testing of Material- 129 STANDARDS

- ISO - International Organisation of standardization- 34 STANDARDS

- BIS - Bureau of Indian Standards -17 STANDARDS

- BS - Brittish Standard- 8 STANDARDS

- BS EN - Europian norms- 36 STANDARDS

ASTM - American Society for Testing of Material:

ASTM's textile standards provide the specifications and test

methods for the physical, mechanical, and chemical properties of textiles,

fabrics, and cloths, as well as the natural and artificial fibers that

constitute them. The textiles covered by these standards are commonly formed by

weaving, knitting, or spinning.

ISO -

International Organisation of standardization:

Today, textiles come from all over the world. They might be formed in

one country, dyed in another, and made into finished goods in yet another. To

ensure that the same practices are used in this complicated international

process, many companies follow agreed-upon standards related to industrial

processes and the goods produced by them. These standards are called ISO

textile testing standards.

following ISO standards can help to ensure consistent quality of the raw

materials being used to make textiles, which in turn improves the final

product. Adhering to ISO standards can also help lower operating costs and

ensure quality management. Following ISO standards often involves inspection

and testing at each stage of a process. For example, raw materials might be

tested, then dyed fabrics, and finally finished goods.

BIS-Bureau of Indian

Standards:

The Bureau of Indian

Standards (BIS) is the national standard organisation of India under the aegis

of Ministry of Consumer Affairs, Food & Public Distribution, Govt of India.

It was founded on 1st April 1987, replacing the Indian Standards Institute. The

Bureau is a body corporate and responsible for formulating national standards.

It comprises of members representing the Industry, Consumer Organizations,

Scientific & Research Institutes and Professional Bodies, Technical

Institutions, Central Ministries, State Governments and Members of Parliament.

The Indian Standards are formulated keeping in view national priorities,

programmes for industrial development, technological needs, export promotion,

consumer welfare, health, safety, etc. So far over 17000 standards have been

formulated in different technology areas.

Methods used for testing of geotextile material:

- Determination of Mass per unit Area:

This

standard explains a method to determine the mass per unit area of all natural

geotextile. The mass per unit area is calculated by weighing small square

specimens of known dimensions. Ten specimens of 100cm2 are cut from the

material in such way that they are representative of the material to be tested.

The area and weight of the specimens are determined to an accuracy of 0.5 and

0.1 % respectively.

The mass

per unit area of each specimen is calculated using the equation p= (m X 106 )

/a

Where

p=mass/unit area in g/m2

m=mass of

the specimen in, g

a=the area

of the specimen in mm2

The

average mass per unit area is calculated.

- Determination of Thickness:

This

standard describes a method for the determination of the thickness of

geotextiles at specified pressures. The distances between a reference plate on

which the specimen rests and a parallel presser-foot applying the given

pressure to the specimen is define as the thickness of the geotextiles. A

thickness tester apparatus capable of exerting a pressure of 2kPa is used. Test

specimen shall be cut from the material from positions evenly distributed over

the full width and length of the sample. The specimen is placed between the

surfaces of the reference plate and pressure foot of the thickness tester. The

presserfoot is load gentle over the specimen by applying a pressure of 2±0.01

kPa. The gauge reading is noted after 30 seconds. Remove the pressure and the

specimen. The procedure is repeated for at least ten specimens. The average of

all the readings is reported as the thickness of the geotextile. The thickness

is expressed in mm to an accuracy of 1% for geotextiles thickness over 0.05mm

and to the nearest 0.001mm for thickness not exceeding 0.05mm.

- Determination of Percentage of Swell:

This

standard prescribes method for determination of the percentage of swell in

water of geo textiles after it has been immersed in water for 24 hours. Ten

specimens of size 100mmx100mm are used for the test. The thickness of each

specimens is noted on thickness tester and recorded as the initial thickness ti

to the nearest 0.01mm. Now place the specimen between the two No.17 gauge wire

mesh screens that have been soaked in water for a minimum of one hour .The

screen corners are connected loosely to hold the test specimen in place. The

test specimen is immersed in deionized water for 24 hours. After the soaking

period, the specimen is removed from the assembly after allowing the water to

drain of. The thickness of the drain specimen is measured as tf. The percentage

thickness change or swell is calculated as,

Percentage

thickness change=100(tf - ti)/ ti

The

procedure is repeated for 10 specimens.

- Determination of Water Absorption Capacity:

This

standard describes the method for determination of the water absorption

capacity of geotextiles. A galvanized screen and pans are used for this method.

Three specimens measuring 200mm x 200mm are prepared and weight the nearest

0.1g. Each specimen is placed on a tared 230mm x 230mm galvanized wire screen. Another

tared screen having similar dimension is placed over the specimen. Now both

screen and specimen is placed in a 76mm deep pan containing water at about 75mm

deep. The specimen is allowed to soak for 24 hours. After the soaking period

the specimen and the screens are allowed to drain for 10 minute and then

weighed to the nearest 0.1g. The amount of water held by the specimen is

calculated by subtracting the sum of the weights of the weighing pan, screens

and dry specimens from the total weight. The absorptive capacity is a ratio of

the water held by the specimen to the weight of the original dry specimen.

To eliminate the high degree of variability

from the Mullen Burst (3786) and Pin Puncture (4833) test methods, Static (CBR)

Puncture Strength (ASTM D 6241) was developed to replace them. CBR stands for

California Bearing Ratio, a soil strength test that was adapted for this

geotextile test. CBR Puncture is an index of puncture resistance that measures

the force required to push a flat ended plunger through a geotextile. A 150 mm

geotextile sample is secured between two steel rings. Instead of an 8 mm

diameter probe with a beveled edge (Pin Puncture 4833); this test utilizes a

50mm diameter, flat-ended probe (plunger) that is pushed slowly through the

geotextile. The relatively large size of the plunger provides a

multidirectional force on the geotextile and simulates big stones pressed onto

a geotextile laying a relatively soft sub-base.

- CBR Puncture:

To eliminate the high degree of variability

from the Mullen Burst (3786) and Pin Puncture (4833) test methods, Static (CBR)

Puncture Strength (ASTM D 6241) was developed to replace them. CBR stands for

California Bearing Ratio, a soil strength test that was adapted for this

geotextile test. CBR Puncture is an index of puncture resistance that measures

the force required to push a flat ended plunger through a geotextile. A 150 mm

geotextile sample is secured between two steel rings. Instead of an 8 mm

diameter probe with a beveled edge (Pin Puncture 4833); this test utilizes a

50mm diameter, flat-ended probe (plunger) that is pushed slowly through the

geotextile. The relatively large size of the plunger provides a

multidirectional force on the geotextile and simulates big stones pressed onto

a geotextile laying a relatively soft sub-base.

- Permittivity:

Permittivity

is the mechanism by which water moves through the fabric. The permittivity test

measures the quantity of water which can pass through a geotextile

perpendicular to the surface of the geotextile. The permittivity may be

measured either in a constant head or falling head test, although constant head

testing is more common due to the high flow rates through geotextiles which

make it is difficult to obtain readings of head change versus time in the

falling head test. In the constant head test, a head of 50 mm water is

maintained on the geotextile throughout the test. The quantity of flow is

measured versus time. In the falling head test, a column of water is allowed to

flow through the geotextile and reading of head changes versus time is taken.

The flow rate of water through the geotextile needs to be slow enough to obtain

accurate readings.

The Bombay Textile Research

Association (BTRA) was registered by members of the Millowners' Association,

Bombay, under the Societies Registration Act, XXI of 1860 on 21st April 1954,

with nine mill companies contributing to the Memorandum and Articles of

Association. In the past 25 years many applications of geosynthetics have

proved their value in civil engineering projects and this new class of material

has added entirely a new dimension to the world of geotechnical engineering.

Geosynthetic materials like Geotextiles, Geogrids, Geonets, Geocell, and

Geomembranes are used in various civil engineering activities especially in

highway engineering to facilitate construction, ensure better performance of

the structure and reduce maintenance. To know the performance of these

products, performance evaluation is to be done & to meet the requirements,

quality has to be maintained.

The standard is not directly

concerned with the actual properties or design of product but with gaureenting

that the product is always manufactured in the same way, to the same

specifications, that no substandard raw material used in the production and

that any rejects do not find their way into the output. The concerns of the

standard are really with good organizational practice and it involves complete

documentation of the whole process together with internal and external checks

to ensure that everything is being run according to these written instructions.

Testing staff having skill

in sample preparation, handling of test equipments, knowledge of quality system

and test standards. Experience in testing of similar products & various

tests will have better influence on quality of testing. The staffs are trained

time to time for various tests, quality control systems and interpretation of

results. Calibration of test equipments is done periodically ( every year ).

Quality audit is carried out by NABL every year. The Laboratory implements new or

revised test.

Common Tests of Geotextile:

- Mass : gms per meter square

- Thickness at specified pressure

- Tensile strength : Strip / Grab / Wide Width

- Tear Strength : Trapezoid

- Water Permeability : Vertical / Horizontal

- Apparent Opening Size : Sieving method

- Puncture Resistance : CBR / Index / Cone

It is

pertinent to mention that BTRA is the first institute in India and probably

only the third institute outside USA to get this coveted accreditation. What

this means to the geosynthetics producers and users is that they can get the

products tested in BTRA with utmost confidence that the accuracy of the results

are as good as any other GAI-LAP accredited laboratories. They can get the

tests done in India, thus saving time and money without compromising on the

quality of the results.

Result and Disscusion:

Considering

environmental impact, geotextiles should be collected from the project site.

The test which we normally do in isolation that may not be suitable for most of

the geotextile testing. So, we have to get the sample collected from the exact

site and then the sample should be tested in the laboratory. Now there are

standards for collection of test specimens. (Refer Slide Time: 13:26) So, this

standards are ASTM D4354 which is standard practice for sampling of geo

synthetics for testing, then ISO 554 which is specifying the standard

atmosphere for conditioning and or testing specifications ISO 9862 Geotextile

sampling and preparation of test specimen. So, during production and

construction time, test specimens are collected at specified interval. The

number of specimens to be collected for testing is given in the concerned

standard. So, we have to collect the specimen from the site.

So, there

are two different types of test which are conducted on geotextiles. One is

called index testing or in isolation test, which actually test in the

laboratory condition. So, only the tests are performed on geotextile next is

that its called performance test what is that? The performance test are

performed along with site specified soil and conditions. So, index test will

only give an idea and comparative value between the geotextiles which is good

or which is bad comparatively, but the better geotextiles as per index test may

not perform well in performance test. Because in performance test we have to

test along with the site specified soil and site specified condition. So, there

are different types of tests conducted on geotextile materials, these are

physical testing, mechanical test, hydraulic test, endurance test degradation

test. So, we were discuss each and every methods.

Conclusion:

- test methods are a means to understand the product

- test results give a true picture of the product

- test results are dependable when conducted exactly as per the standard

- methods for testing of geotextile materials is important for determine the properties of geotextile materials. The properties are affected on construction in where use of materialthat’s mean a testing should done best way and without any errors. Hence these paper describe the all information for testing of geotextile.

References:

- Geotextiles - TestResources

- www.technotex.gov.in › TES...PPT

- Web results

- TEST METHODS FOR GEOTEXTILES

- https://www.astm.org › Standards

- ASTM D4595 - 17 Standard Test Method for Tensile Properties of Geotextiles by

- https://nptel.ac.in › Lecture-8PDF

- Web results

- Testing of Geosynthetics - Nptel

5 Comments

Nice content.

ReplyDeleteNice piece of information and really informative stats!

ReplyDeleteLay bhari, kdk bhava

ReplyDeleteUseful article

ReplyDeleteVery informative 👍

ReplyDeleteNew comments are not allowed.